A brighter future

through

Lili Lamps is combining quality design with sustainable global thinking.

Our existance is the by-product of a conflict between love for design and wanting to improve the planet for future generations.

Design for all

Lili Lamps is a dream come true for the small designer, manufacturer and marketer: A direct way to market!

In our world...

One print is all it takes

<!–more–>

One of our production partners from USA, Maxwell Winslow, CEO of Wellan.

In our world...

Borders do not exist

We believe that anyone can be part of our vision and journey, so we don’t limit ourselves to one border. By having a global social sustainable mindset, we can include anyone passionate about design, even if they live in Australia or Singapore.

Without limiting ourselves to one supplier, designer, or market, we can effortlessly design and sell our and your products worldwide.

In our world...

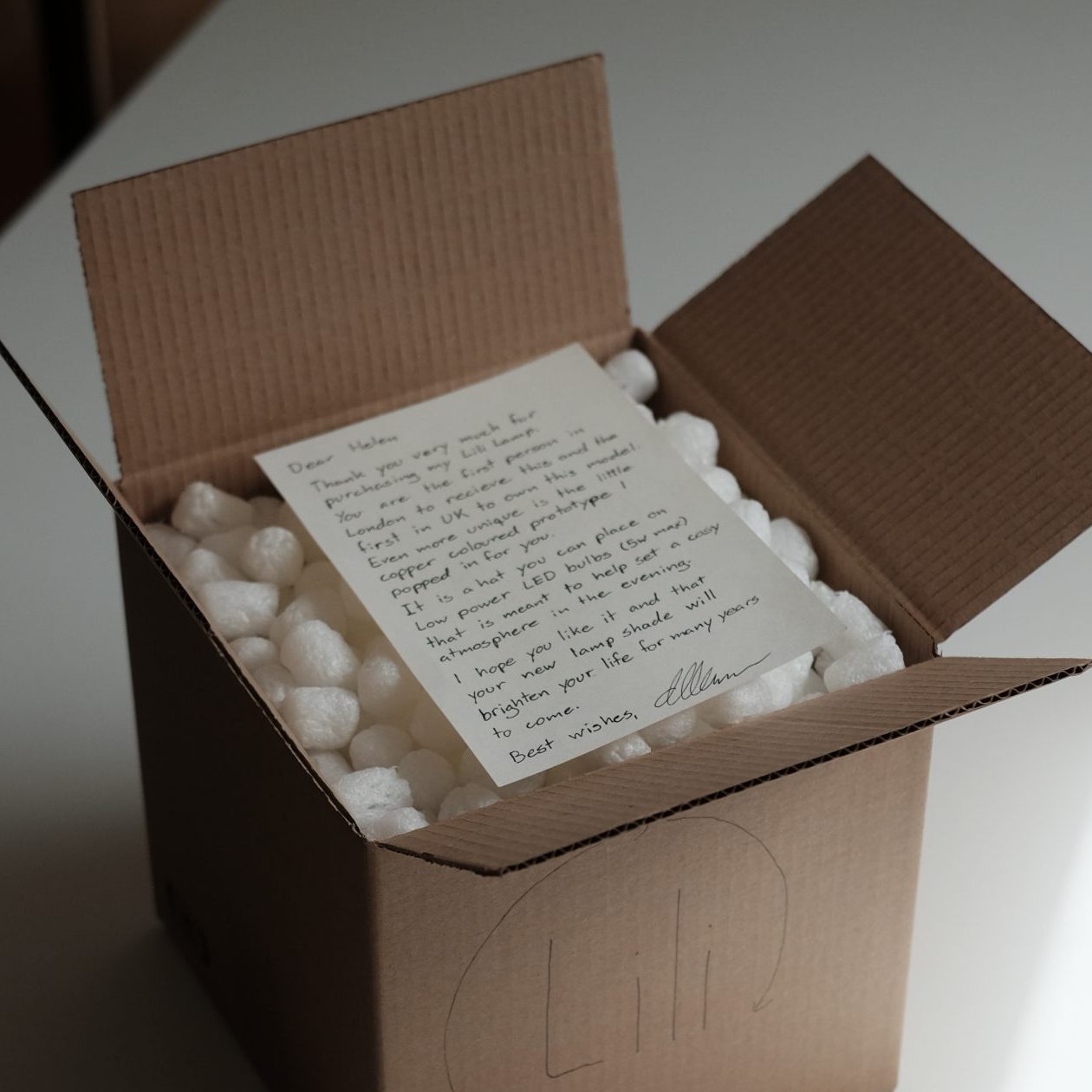

Products are personal

Every product is already owned when it is made. Someone has always needed that product to exist, so it was made for them. And it is their product.

We believe that making every customer invest in the creation of their product makes it worth more than the mere looks and resources. So they care more for it and keep it longer.

And participating in the creation gives you a sense of power that you can improve on the product. Repair it, or make it your own, so it will constantly adapt to your life.

In our world...

Everything is new

As a designer, one of the best parts about this way of producing is the complete freedom.

Being able to make organic and impossible shapes is fantastic; working with a relatively new medium in the product world provides a very satisfying challenge.

And the way that the lines tell the story of the very personal and true nature of the item is just fascinating – you couldn’t do that with any other product.

Fair for all

Lili Lamps is cutting out everyone who has not brought the product to life.

In our world.

Everything is shared fairly

At Lili Lamps, our goal is to assure sustainable and fair design worldwide by using modern technology. Just like the product is only made to order, everything surrounding it is kept simple and honest.

By working directly with the manufacturer, we can achieve a healthy social standard that doesn’t depend on huge orders.

With this concept, we can optimise all processes so those involved benefit most- this is social and local sustainability at its finest!

One of our production partners from England, Daniel, CEO of HandyDans 3D Prints.

In our world...

You do you

We never need to rush or force work on our partners when everything is made through small subsuppliers. Everything is an offer, so no one is forced to do anything. And if you don’t have time, no problem, we will ask again another time.

We make every possible effort to make working as a subsupplier for us as easy and convenient as possible.

We have prepared all materials and workflows, so you must do what you do best: print!

Sustainable for all

Lili Lamps is a new breed of super sustainable products, where every phase of its life is designed to be biofriendly.

In our world...

There is less than 100 km from Denmark to Australia.

As Lili Lamps materialise near every custom, every sale saves thousands of kilometres in transport. A contribution that is both locally and environmentally sustainable.

With Lili Lamps we have created a global design possible of being produced locally anywhere in the world, as long as the given location has access to power, internet and a 3D printer.

The design even adapts to the local hardware, so that this doesn’t need to be imported.

Handy Dan made a soap bar holder from discarded prints.

In our world...

Products live several lives

Since our Lamps are 3D printed and made out of biodegradable materials, they are meant to fulfil their original purpose, while adapting to new ones, more than once.

If you find the need for a pendant lamp more than your table lamp, you can simply rebuild it to fit this purpose. All parts are included.

If the lamp is damaged, the stiff materials crack very sharply and can easily and often seamlessly be glued together again. If this does not work, the materials can be remelted several times to fit a new purpose.

In our world...

All is natural

We find the best way to be sustainable is to only use natural replenishable ressources whenever possible.

The materials we use are mostly made of corn, sugar cane or wood, that process a lot of CO2 while growing.

In our world...

All is used

See the thin line around the print? We almost can’t, because this is all the waste that is generated by a lamp.

When we produce every single lamp to order, we have no stock lying around waiting for a lucky owner.

And, if a production should fail, there are tons of things that we can do to repurpose the material. Some of our producers even melt it into new products, like Daniel from UK did here.

In our world...

You give back

One condition to be a part of our world is to only use materials that are at least biodegradable. That means that they can return to earth under proper conditions.

This is of course only applicable to the 3d printed parts, but we are doing our best to source sustainable hardware as well – A favourite material we use is PLA, which will biodegrade in an industrial waste facility.

At Lili Lamps our drive is to find the best sustainable solutions through modern technology. We do this by not limiting ourselves to one way of thinking and by educating ourselves in new biodegradable technologies each day. This is our way of giving back to Earth.

Let us enlighten you

Be the first to know about all the good stuff

A lot is happening with Lili Lamps, and we would love to invite you into our expanding crazy world, where design is democratized, everyone gets a fair share and every product leaves the world brighter in many ways.